Tempering is a critical process used in the production of tempered glass, which is much stronger and safer than regular glass. The process involves heating the glass to a very high temperature and then rapidly cooling it.

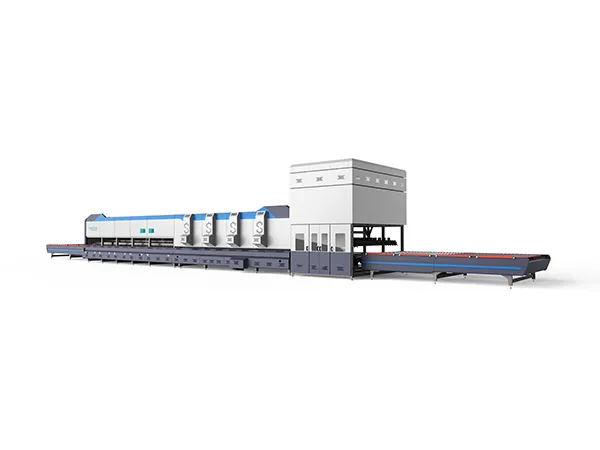

Glass tempering furnace process

Preparation: Before the glass can be tempered, it needs to be cut to the desired size and shape. This can be done using various cutting and shaping techniques.

Cleaning: The glass is thoroughly cleaned to remove any dirt, dust, or other impurities that could affect the tempering process.

Heating: The glass is placed into a tempering furnace, which heats it to a temperature of around 600-700°C (1112-1292°F) or higher depending on the type of glass and its thickness. This heating process softens the glass and makes it more pliable.

Quenching: After reaching the desired temperature, the glass is rapidly cooled by blowing air onto its surface or by immersing it in a high-pressure air stream. This rapid cooling causes the outer surfaces of the glass to cool much faster than the center, creating a state of high compression in the outer layers and tension in the center.

Annealing: Once the glass has been tempered, it undergoes a process called annealing to relieve any remaining internal stresses and ensure uniformity of the tempered glass. This involves slowly cooling the glass to room temperature in a controlled manner.

Inspection: The tempered glass is inspected for any defects or imperfections that may have occurred during the tempering process. This includes checking for surface flaws, optical distortion, or any other issues that could affect the quality and safety of the glass.

Packaging and Shipping: After passing inspection, the tempered glass is packaged and prepared for shipping to its final destination, where it will be used in various applications such as automotive, architectural, or household purposes.

Overall, the glass tempering furnace process is crucial for enhancing the strength and safety of glass products, making them suitable for a wide range of applications where safety and durability are paramount.