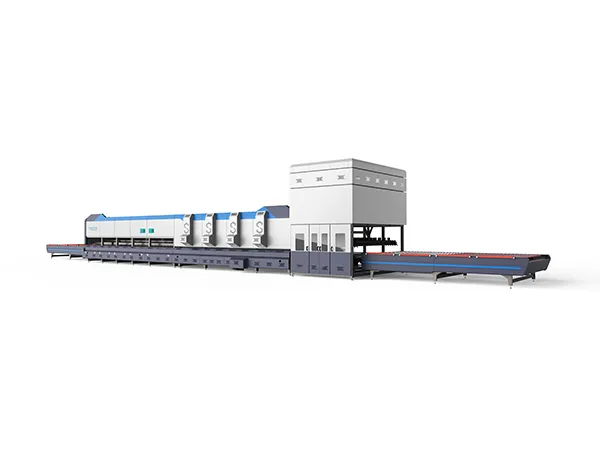

There are many types of glass seen in daily life, and the glass tempering furnace equipment used in production is also very different. In addition, the glass tempering furnace is non-standard equipment. You also need to pay attention to skills when purchasing a glass tempering furnace. At the same time, when purchasing When purchasing glass tempering equipment, the factory area, production environment, and power conditions of the glass deep processing enterprise must be considered.

Glass tempering furnace selection

1. Glass tempering furnace selection basis

Capacity matching: The tempering furnace production capacity must match the estimated annual comprehensive output. Enterprises can back-calculate the required tempering furnace production capacity based on the estimated annual output, so as to select a suitable tempering furnace model.

Site area: Different furnace types, such as flat tempering furnaces, curved tempering furnaces, flat and curved two-way tempering furnaces, double-chamber furnaces, continuous furnaces, etc., vary greatly in longitudinal length. Customers should select based on the actual reserved area. In addition, It is also necessary to consider the space reserved in the temporary storage area of the work-in-progress glass before and after the tempering furnace.

Electric power load: Different furnace types have different installed powers. Enterprises should consider the factory’s existing transformer installed capacity and expansion possibilities for comprehensive selection. Competitors' equipment situation: Based on the consideration of differentiated competition, the selected size of the tempering furnace is generally larger than the equipment size of regional competitors. For example, the furnace size of surrounding competitors is 2.4 meters * 5 meters, and the selected size is 2.4 meters * 6 meters or 2.8 meters*5 meters in size.

2. Select according to the implementation function

At present, the main forced convection tempering furnaces on the market include: flat tempering furnace, curved tempering furnace, flat and curved two-way tempering furnace, curved and curved two-way tempering furnace, and unequal arc tempering furnace. Different types of tempering furnaces have different uses. You can choose the tempering furnace function according to your needs. For example, in terms of construction, large pieces of flat glass are mainly used, and the main function to be considered is flat tempered glass. Of course, if you want a wider product coverage, you can consider a flat and curved bidirectional tempering furnace, which can make both flat and curved glass. Of course, the cost of such a tempering furnace will be relatively high.

3. Confirm product positioning

The tempered glass market can be divided into B-end customers (more regular orders) and C-end customers (more scattered orders). B-end customers, that is, engineering orders, are further divided into door and window glass and curtain wall glass. Generally, the product specifications are neat; C-end customers Customers, that is, the home decoration market, are divided into high-end system windows and general home windows. Among them, B-side curtain wall glass and C-side system windows have very high requirements for imaging and glass surface quality, so the equipment configuration requirements are also high, so customers should choose according to their own requirements. Product positioning, choose a tempering furnace with appropriate configuration.

4. Look at the strength of the manufacturer

Choose a well-known brand. Tempering furnace technology is a comparative technology. Large manufacturers have their own R&D teams, and product quality and after-sales service are guaranteed. In addition, large manufacturers provide non-standard equipment, which can be customized and modified according to the actual needs of customers to better meet production requirements. From design drawings to equipment debugging to post-service, it is a lot of worry.

5. How to choose between upper and lower full convection ovens and upper semi-convection ovens

The upper semi-convection furnace uses air convection to heat the upper surface of the glass, and the lower part uses traditional radiation heating. It is suitable for customers who have a small amount of Low-E glass orders. The full convection tempering furnace also has a convection device in the lower part to enhance heat transfer in the lower part. This avoids defects such as spherical bending caused by the heat transfer rate of the upper surface of the glass being significantly higher than that of the lower surface of the glass when heating large plate glass or coated glass less than 4mm without lower convection; The surface is heated simultaneously, so the glass heating quality is better and the production efficiency is higher. At the same time, the full convection tempering furnace can better heat Low-E glass with complex film systems.

6. How to choose between forced convection furnace and radiant furnace

When it comes to forced convection, we must mention Low-E glass. Low-E glass is known for its low-radiation properties. Simply put, it reflects a large amount of radiation and heat transfer, so it is difficult to heat it quickly by radiation. For radiant furnaces, when low-E glass is heated, the radiant heat transfer time is too long, and the upper and lower surfaces of the glass are heated unevenly, seriously affecting the quality of the glass. The forced convection furnace uses air convection heating to directly blow heat to the glass surface, overcoming the problem of reflection of radiant heat on the surface of Low-E glass. Therefore, when the processing volume of coated glass in an enterprise's order exceeds 30% or the variety of glass processing In many cases, a convection furnace is suitable. Even when processing ordinary white glass, the performance of a convection furnace is significantly better than that of a radiant furnace. Therefore, it is generally recommended that companies choose a forced convection tempering furnace.

The above is the answer to how to choose a tempering furnace. In addition, when purchasing a glass tempering furnace, the comprehensive performance, after-sales service, and subsequent maintenance of the tempering equipment are all factors that should be considered.