There are several types of tempering furnaces used in the glass industry, each with its own advantages and applications.

Tempering furnace type

Convection Furnaces: Convection furnaces use fans to circulate hot air evenly around the glass panels. This ensures uniform heating, which is essential for achieving consistent tempering results. Convection furnaces are often preferred for tempering low-E (low emissivity) glass and other specialized glass types.

Radiation Furnaces: Radiation furnaces use infrared heating elements to heat the glass panels. These heating elements emit infrared radiation, which is absorbed by the glass surface, causing it to heat up. Radiation furnaces are known for their energy efficiency and fast heating rates.

Top and Bottom Heating Furnaces: In these furnaces, the glass panels are heated from both the top and bottom sides simultaneously. This ensures uniform heating and helps prevent distortion during the tempering process.

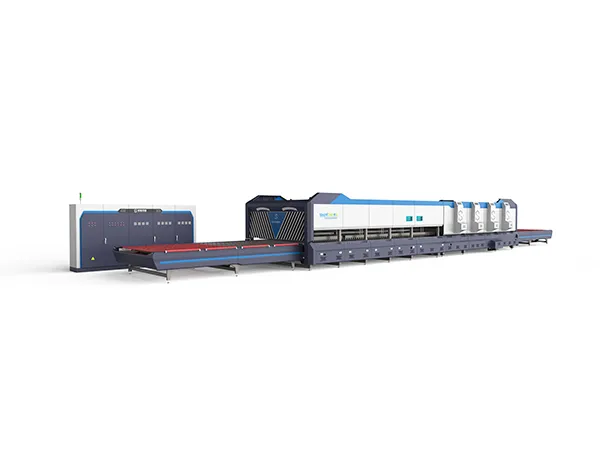

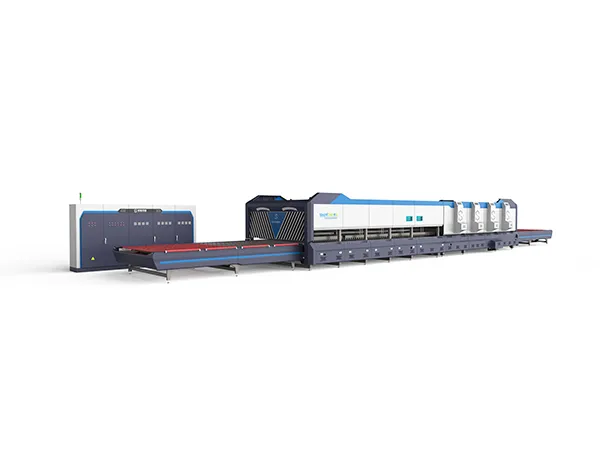

Roller Hearth Furnaces: Roller hearth furnaces use a system of rollers to transport glass panels through the heating and cooling zones of the furnace. This continuous processing method is well-suited for high-volume production and can achieve consistent tempering results.

Bend Glass Furnaces: These furnaces are specifically designed for tempering bent or curved glass panels. They use specialized molds or bending mechanisms to shape the glass during the tempering process.

Chemical Strengthening Furnaces: While not strictly tempering furnaces in the traditional sense, chemical strengthening furnaces are used to strengthen glass through a chemical process involving ion exchange. These furnaces immerse glass panels in a bath of molten salt or other chemical solutions to create a compressive stress layer on the surface of the glass, increasing its strength.

Each type of tempering furnace has its own advantages and limitations, and the choice of furnace depends on factors such as the type of glass being tempered, production requirements, and budget considerations. Manufacturers often offer a range of options and customization features to meet the specific needs of their customers.